The 0247-9 SAE J1939 Data Link Abnormal Update Rate fault indicates a communication issue on the J1939 CAN data link. The steps below outline how to troubleshoot and resolve the issue systematically.

Preparations:

Perkins EST 2024A & 2023A & 2019A Software Free Download

Perkins SPI2 2018A EPC+Service Manual Free Download

Perkins Communication Adapter 3

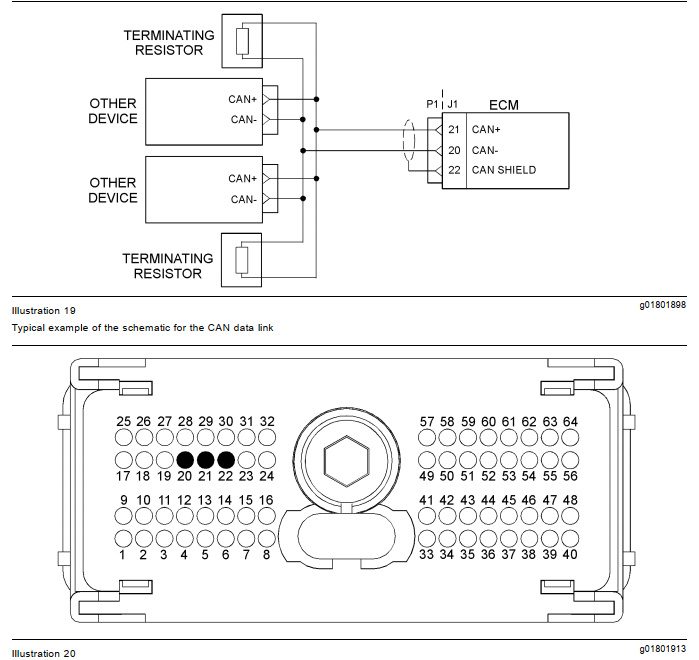

Overview of the J1939 Data Link

- The J1939 data link enables high-speed communication between devices.

- Proper communication requires 60 ohms resistance between the CAN_H and CAN_L lines, achieved by two 120-ohm terminating resistors at each end of the network.

- The J1939 cabling is a shielded twisted pair, and any damage must be replaced with the same type of cable.

Step-by-Step Diagnostic Procedure

Test Step 1: Inspect Electrical Connections and Wiring

- Turn off the ignition switch.

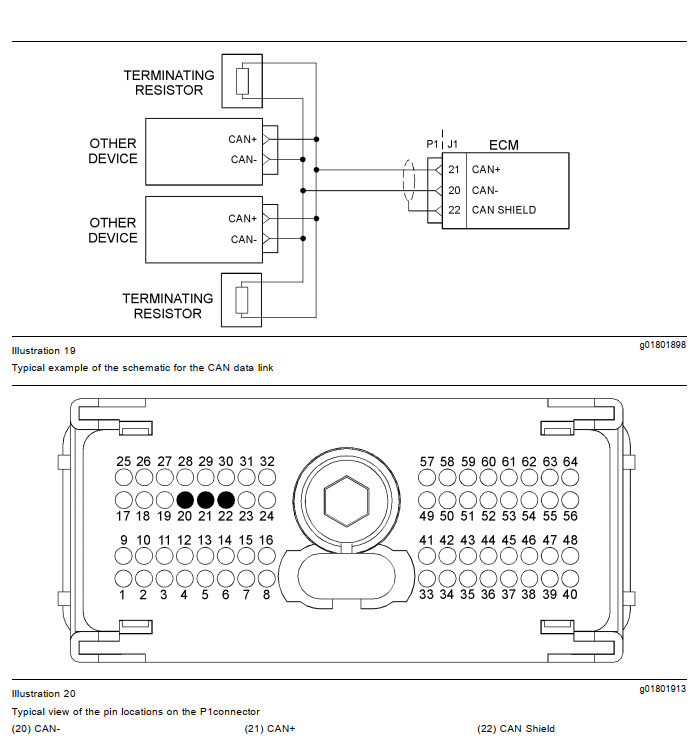

- Inspect all connectors on the CAN data link circuit (e.g., P1/J1 connectors).

- Perform a 45 N (10 lb) pull test on all cables connected to the data link.

- Check the wiring harness from the ignition switch to the ECM for signs of:

- Corrosion

- Wear or damage

- Pinching or other physical defects

Expected Result:

All connections are fully seated, and the wiring is intact.

Outcome:

- OK: Proceed to Test Step 2.

- Not OK: Repair or replace the connector/wiring as needed. Clear diagnostic codes and verify resolution. STOP.

Test Step 2: Check the Terminating Resistor

- Disconnect the P1 connector from the ECM.

- Use a multimeter to measure resistance between P1:20 (CAN_H) and P1:21 (CAN_L).

Expected Result:

Resistance should be 50–70 ohms.

Outcome and Actions:

- 50–70 ohms (Result 1): The terminating resistance is correct. Proceed to Test Step 3.

- Less than 50 ohms (Result 2): Short circuit in the wiring harness. Repair or replace as needed, clear codes, and verify. STOP.

- 110–130 ohms (Result 3): One terminating resistor may be faulty.

- Locate and test both terminating resistors.

- Replace any resistor outside the 50–70 ohm range.

- If both resistors are good, proceed to Test Step 4.

- Greater than 150 ohms (Result 4): Open circuit in the wiring harness. Proceed to Test Step 3.

Test Step 3: Verify Data Link Cabling

- Disconnect any additional devices connected to the J1939 data link.

- Measure resistance between the following pairs of pins:

- P1:20 (CAN_H) and other CAN+ pins.

- P1:21 (CAN_L) and other CAN- pins.

- P1:22 (CAN Shield) and shield pins of other devices.

- Use a multimeter for these measurements.

Expected Result:

Resistance between all cables should be less than 2.0 ohms.

Outcome and Actions:

- OK: All resistances are within limits. Proceed to Test Step 4.

- Not OK: Repair or replace any faulty wiring or connectors, clear codes, and verify resolution. STOP.

Test Step 4: Check Other Devices on the J1939 Network

- Use an appropriate diagnostic tool to test all other devices on the J1939 data link.

Expected Result:

All devices on the data link function correctly.

Outcome and Actions:

- OK: Repeat the entire test sequence from Test Step 1 to confirm resolution. STOP.

- Not OK: Diagnose and repair faulty devices. Clear codes and verify resolution. STOP.

More trouble repair case for Perkins,pls refer to:Perkins Trouble Repair