Introduction

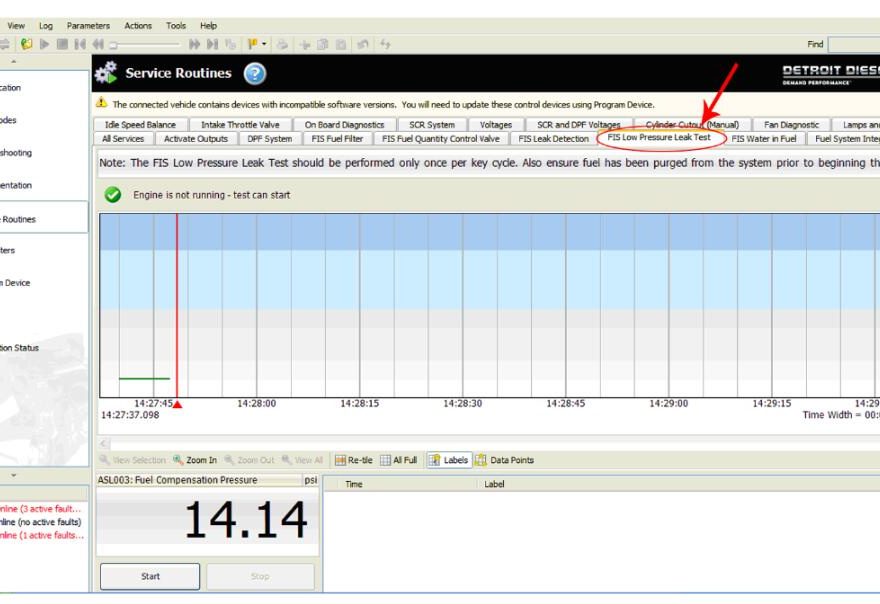

This guide demonstrates how to perform a Fuel Injection System (FIS) low-pressure leak test on a Detroit GHG17 heavy-duty engine using the Detroit Diesel Diagnostic Link (DDDL) software.

Related Content

- 2024 Detroit Diesel Diagnostic Link DDDL 8.19 8.09 Free Download

- JPRO DLA+ 2.0 Adapter

- NEXIQ USB Link Adapter

What You Need

- Diagnostic Software: DDDL 8.19

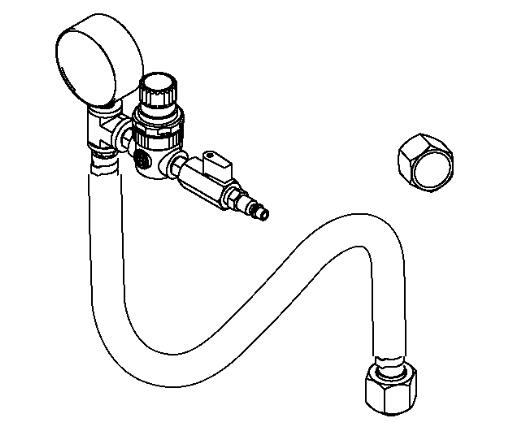

- Air Pressure Test Kit: Fuel System

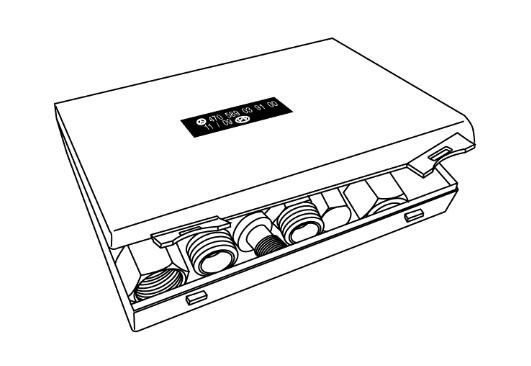

- Fuel System Tool Update Kit without Motor Control Module (MCM) Cooler

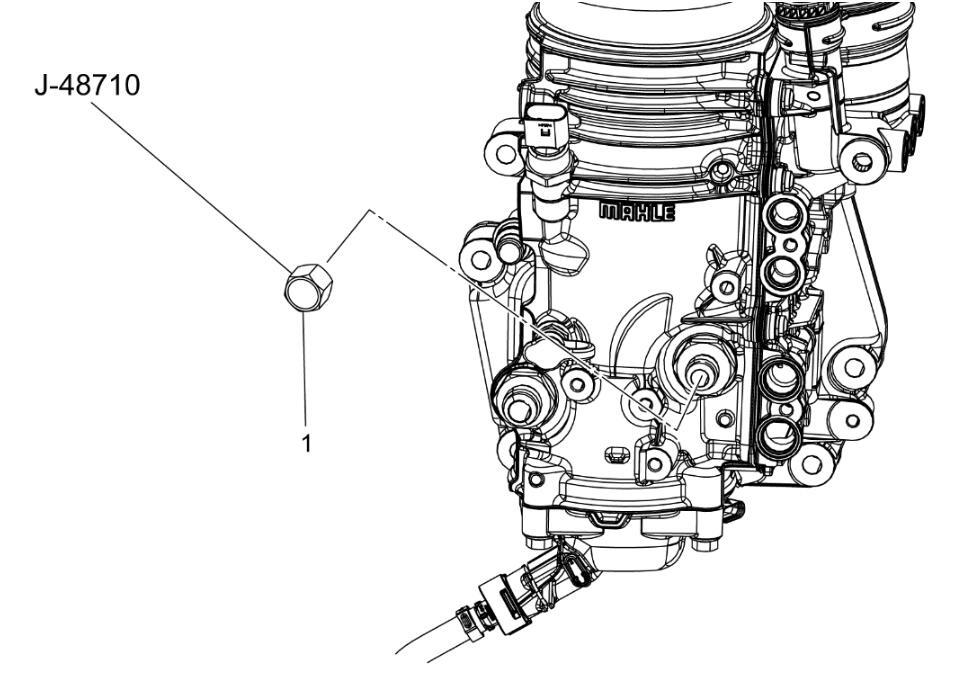

Note: Refer to 13 TL-11REV for updates on Tool J-48710, which enhances leak detection accuracy in low-pressure fuel systems.

Procedure

Preliminary Steps

- Shut off the engine, apply the parking brake, lock the wheels, and take all necessary safety precautions.

- Remove the fuel tank filler cap.

- Disconnect the fuel supply line from the fuel filter module.

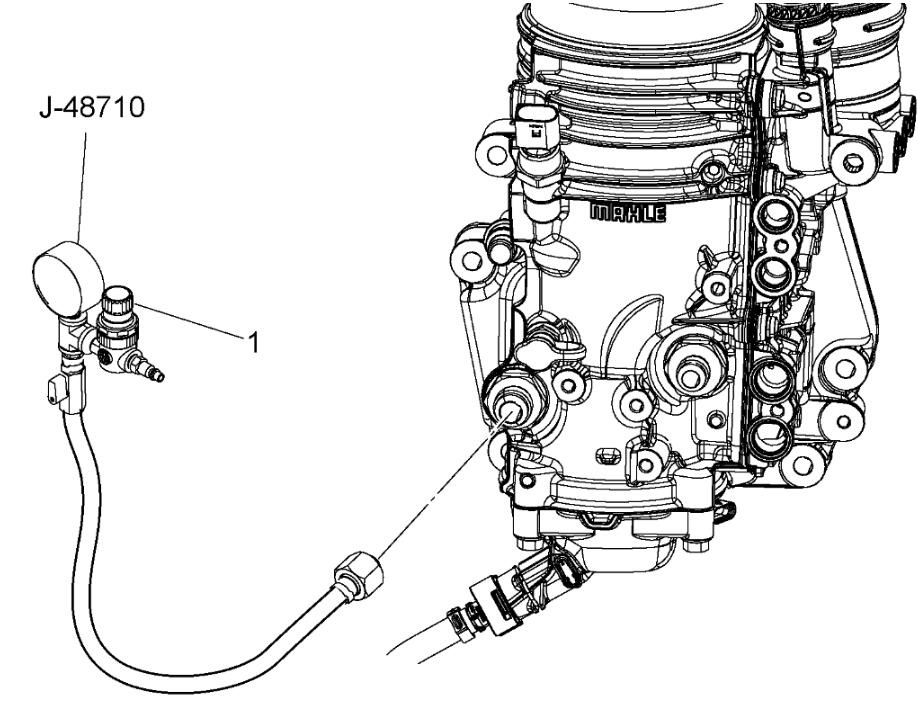

- Install Tool J-48710 onto the fuel filter module.

Pressurizing the System

- Connect the air supply to Tool J-48710.

- Pressurize the fuel system to 517 kPa (75 psi) for six minutes.

- Close the ball valve on Tool J-48710.

- Wait for two minutes.

- Disconnect the return line from the fuel filter module and install the cap Tool J-48710 on the return line connector.

Preparing for Diagnostics

- Install the fuel tank filler cap.

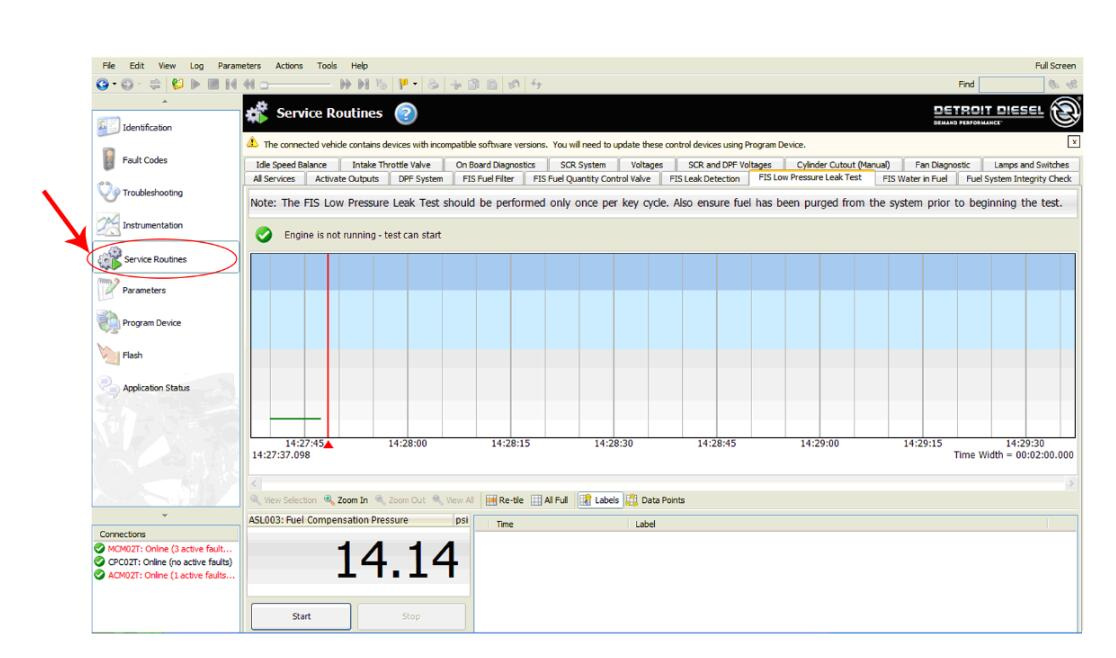

- With the ignition ON and the engine OFF, connect to the MCM via DiagnosticLink.

- In DiagnosticLink, click the Service Routines tab.

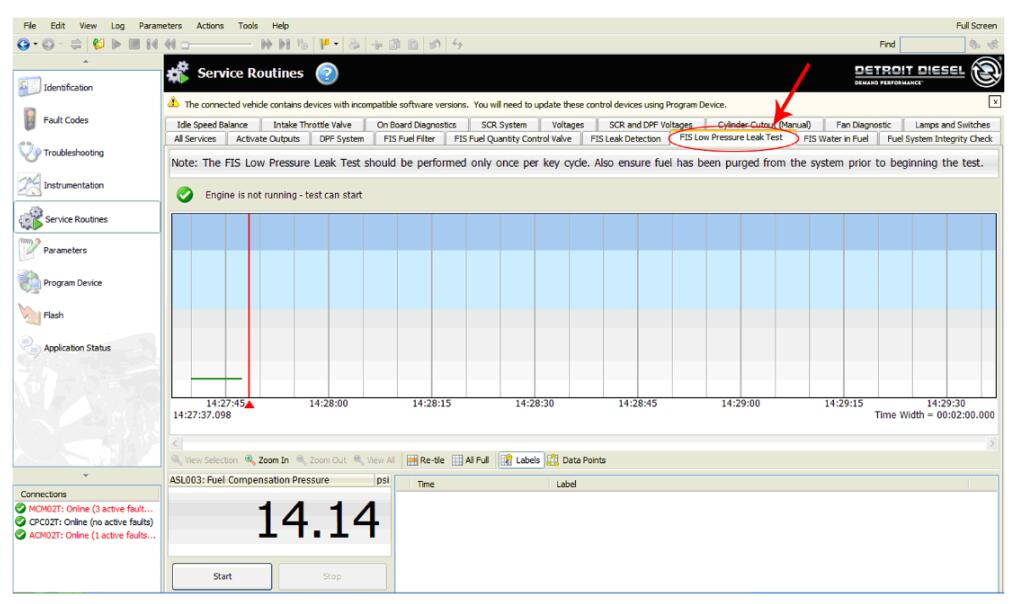

- Select the FIS Low Pressure Leak Test tab.

Running the Leak Test

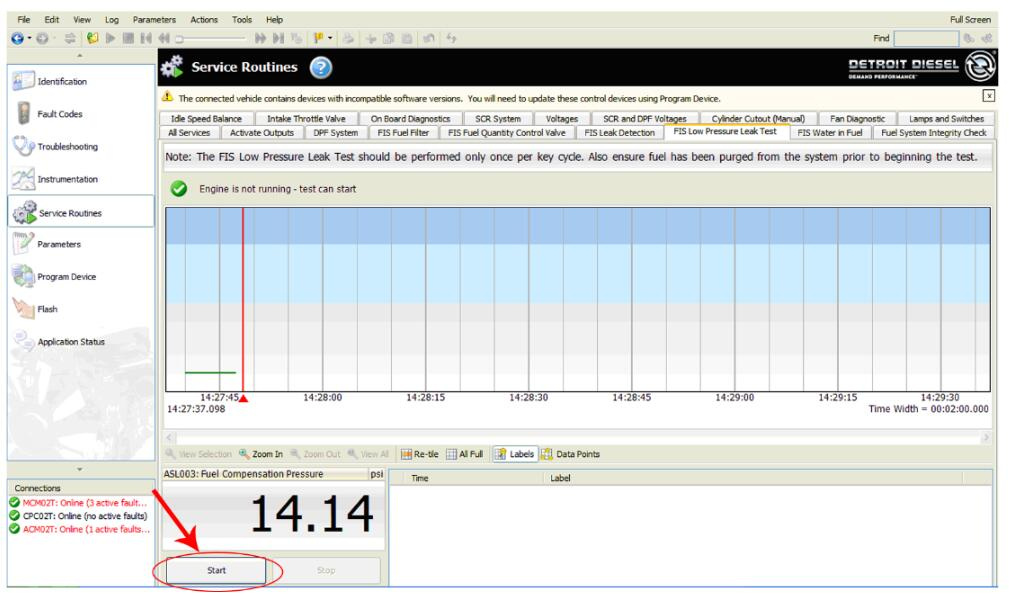

- Use Tool J-48710 to pressurize the fuel system to 517 kPa (75 psi) for four minutes.

- Close the ball valve and disconnect the air supply from Tool J-48710.

Note: The fuel compensation pressure sensor measures absolute pressure. Thus, the indicated pressure should be approximately 100 kPa (14.5 psi) higher than the gauge reading on Tool J-48710. When Tool J-48710 indicates 517 kPa (75 psi), the compensation sensor will show approximately 620 kPa (90 psi).

- Press the “Start” button on DiagnosticLink.

- Once the test is complete, review the test results in the DiagnosticLink log file.

Analyzing the Results

- Did the fuel system pass the FIS Low Pressure Leak Test?

- Yes: Gently remove the cap Tool J-48710 from the fuel filter module. Remove Tool J-48710 from the fuel filter module. Reattach the fuel supply and return lines to the fuel filter module. Return to the original diagnostic that led to the FIS Low Pressure Leak Test.

- No: Proceed to step 19.

If a Leak is Detected

- Reconnect the air supply to Tool J-48710.

- Open the ball valve and pressurize the fuel system to 517 kPa (75 psi).

- Follow the “Possible Fuel Leak – Dual Filter Fuel System” procedure to locate the leak using a soapy solution to spray on fittings, connections, and hoses.

For more Detroit Diesel engine repair cases, visit Detroit Diesel Engine Repair.